Menu

A triptych painting is a form of art that consists of three individual panels, often hinged together, that are meant to be viewed as a single, unified work.

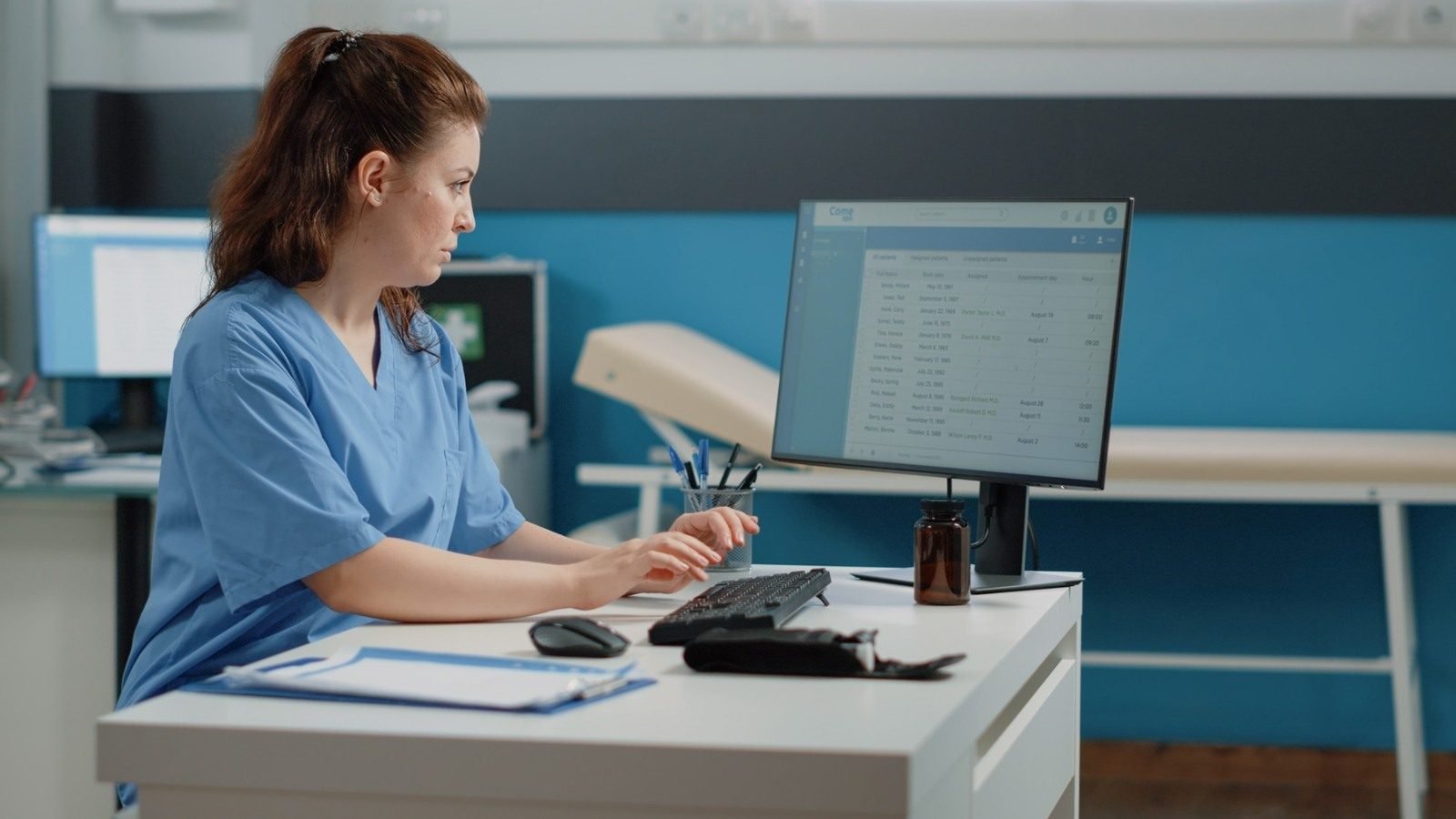

In the fast-paced world of healthcare communications, every message counts. From patient education to marketing pharmaceutical products, clarity and compliance are paramount. With strict regulations governing how health information is shared, ensuring that all communications meet these standards has never been more critical. That’s where content moderation services come into play.

Raspberry Hills | Raspberry Hills Clothing | Save Upto 30%

In the increasingly competitive world of dentistry, providers are constantly seeking new ways to improve profitability without compromising on patient care. One such strategy that has emerged as a changed is dental fee re negotiation.

Get comprehensive umbrella insurance for landlords with Bloomingdale Insurance Services. Safeguard assets with excess liability coverage today.

types of medical waste incinerators

We hope this read was helpful to you! Don’t forget to follow Guest Genius Hub for more relevant and informative content!