In today’s fast-paced manufacturing world, precision, speed, and cost-effectiveness are the driving factors behind successful production processes. Among the various methods employed, CNC Turning stands out as an essential technique, especially for the production of complex components. The use of computer numerical control (CNC) technology has revolutionized the way manufacturers approach precision machining, offering numerous advantages over traditional methods. This article explores why CNC Turning is indispensable for producing complex components, looking into its capabilities, advantages, and the crucial role it plays in industries ranging from aerospace to automotive.

The Fundamentals of CNC Turning

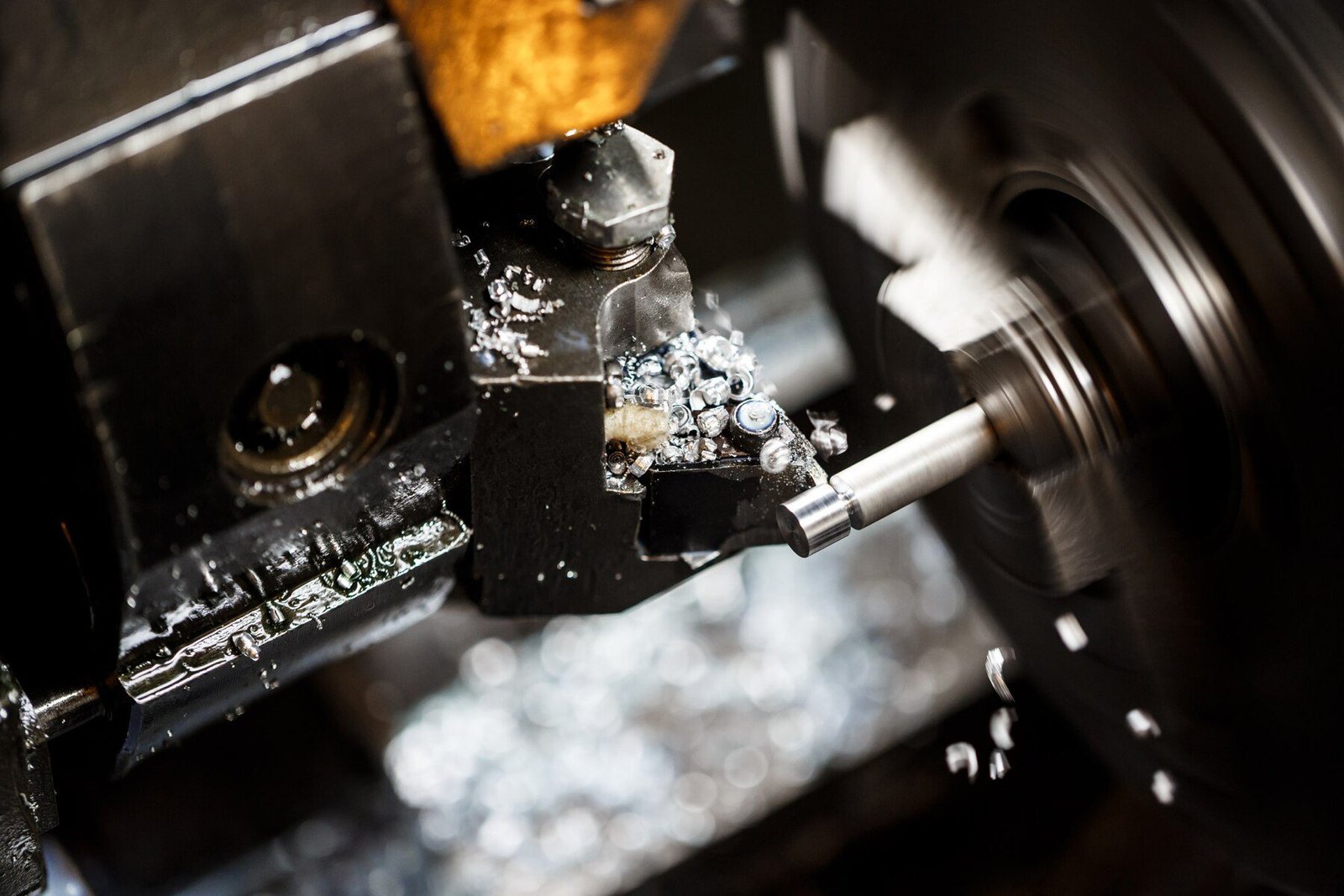

CNC Turning is a process in which a cutting tool is applied to a rotating workpiece to shape it into the desired form. The workpiece is typically held in a chuck and rotated at high speeds while the cutting tool moves along various axes to cut away material. This method is ideal for producing cylindrical and spherical shapes, but it can also be adapted for complex geometries, which makes it especially useful in producing intricate components.

Unlike traditional turning methods, CNC Turning involves the use of a computer-controlled machine that follows pre-programmed instructions. This provides a level of precision and repeatability that is difficult to achieve with manual operation. The ability to input specific designs and receive consistent results makes CNC Turning essential for manufacturers who require high accuracy, especially when working with complex components that demand tight tolerances and intricate features.

Precision and Accuracy for Complex Components

One of the primary reasons CNC Turning is so crucial for complex component production is its exceptional precision and accuracy. With traditional turning, even slight human errors can result in flawed components, requiring rework and additional time to fix. However, with CNC machines, every cut is calculated and executed with millimeter precision, ensuring that the final product is as close to the original design as possible.

The ability of CNC Turning to achieve such high levels of accuracy is vital for industries like aerospace, automotive, and medical device manufacturing, where even the smallest deviation can have serious consequences. Components that need to fit together perfectly, such as engine parts or medical implants, require the precision that CNC Turning can provide. This high level of accuracy reduces the likelihood of defects, ensures better quality control, and enhances the overall reliability of the final product.

Versatility in Producing Complex Geometries

In complex component production, the versatility of CNC Turning is unmatched. The technique allows for the creation of both simple and highly complex geometries, including grooves, threads, and even contours on a workpiece. The ability to perform these tasks without the need for multiple setups or machines streamlines production, saving both time and costs.

For instance, manufacturers can produce intricate shapes such as turbine blades, valve bodies, or custom mechanical parts that would be difficult, if not impossible, to achieve using traditional methods. The versatility of CNC Turning also allows manufacturers to work with a variety of materials, such as metals, plastics, and composites, expanding its range of applications. Whether producing low-volume prototypes or high-volume production runs, CNC Turning offers the flexibility to meet diverse demands across various industries.

Time and Cost Efficiency

When compared to traditional machining methods, CNC Turning offers significant time and cost savings. The automation of the process ensures that components can be produced faster without sacrificing quality, which is particularly advantageous in industries where deadlines are tight. Since CNC machines can operate 24/7 with minimal human intervention, production times are further reduced, leading to quicker turnaround times for customers.

Moreover, the high precision of CNC Turning reduces material waste, as the cutting process is highly efficient and eliminates unnecessary material removal. This makes CNC Turning not only more cost-effective but also more sustainable in the long term. By optimizing material usage and reducing the need for rework, manufacturers can lower their production costs while maintaining high standards of quality.

Integration with Modern Manufacturing Systems

The integration of CNC Turning with modern manufacturing systems enhances its role in producing complex components. Many CNC machines are equipped with advanced software that allows for seamless integration into larger manufacturing systems, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. This integration enables real-time monitoring of production, precise adjustments, and optimization of the entire production process.

Additionally, CNC Turning machines can be linked to other automated systems, such as robotic arms and conveyors, which further increases production efficiency. This makes CNC Turning not just a standalone process, but a vital part of the larger ecosystem of smart manufacturing. In industries where production lines are highly complex, this integration helps manufacturers achieve a streamlined workflow, reduce errors, and deliver high-quality products at competitive prices.

Conclusion

In summary, CNC Turning has become an essential process for producing complex components across a variety of industries. Its precision, versatility, time and cost efficiency, and integration with modern manufacturing systems make it a key player in today’s manufacturing landscape. Whether it’s for the aerospace, automotive, or medical sectors, CNC Turning offers unparalleled capabilities in producing intricate parts with the highest level of accuracy. As manufacturing technology continues to evolve, CNC Turning remains at the forefront, helping businesses meet the increasing demand for complex, high-quality components.